Our focus in food engineering is the characterization of foods based on color analysis and X-ray imaging.

Automated Design of a Computer Vision System

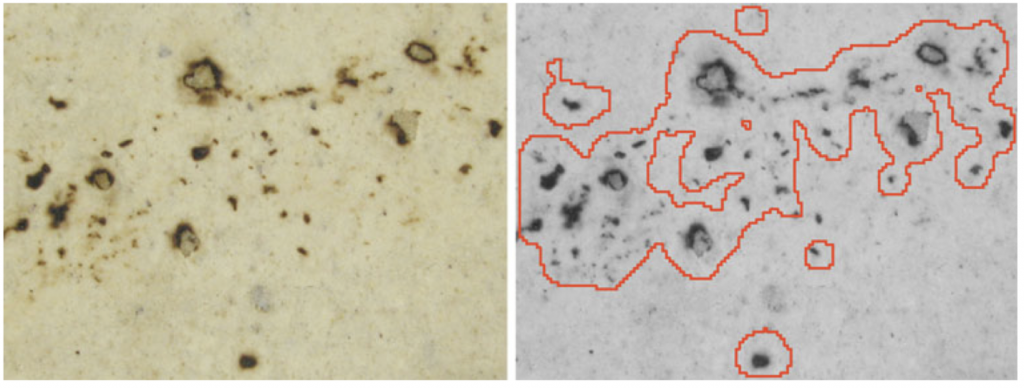

Considerable research efforts in computer vision applied to food quality evaluation have been developed in the last years, however, they have been concentrated on using or developing tailored methods based on visual features that are able to solve a specific task. Nevertheless, today’s computer capabilities are giving us new ways to solve complex computer vision problems. In particular, a new paradigm based on machine learning techniques has emerged posing the task of recognizing visual patterns as a search problem based on training data and a hypothesis space composed by visual features and suitable classifiers. Furthermore, now we are able to extract, process, and test in the same time more image features and classifiers than before. Thus, we developed a general framework that designs a computer vision system automatically, i.e., it finds -without human interaction- the features and the classifiers for a given application avoiding the classical trial and error framework commonly used by human designers. The key idea of the proposed framework is to select from a large set of features and a bank of classifiers those features and classifiers that achieve the highest performance. We tested our framework on four different food quality evaluation problems yielding a classification performance of 96% or more in every case. The proposed framework was implemented as a Matlab Toolbox available for non commercial purposes. See Toolbox in Matlab.

Automated design of a computer vision system for visual food quality evaluation. Mery, D.; Pedreschi, F.; and Soto, A. Food and Bioprocess Technology (2013).

Quality Classification of Corn Tortillas using Computer Vision. Journal of Food Engineering, Mery, D.; Chanona-Perez, J.; Soto, A.; Aguilera, J.M.; Cipriano, A.; Velez-Riverab, N; Arzate-Vazquez, I, Gutierrez–Lopez, G., Journal of Food Engineering (2010).

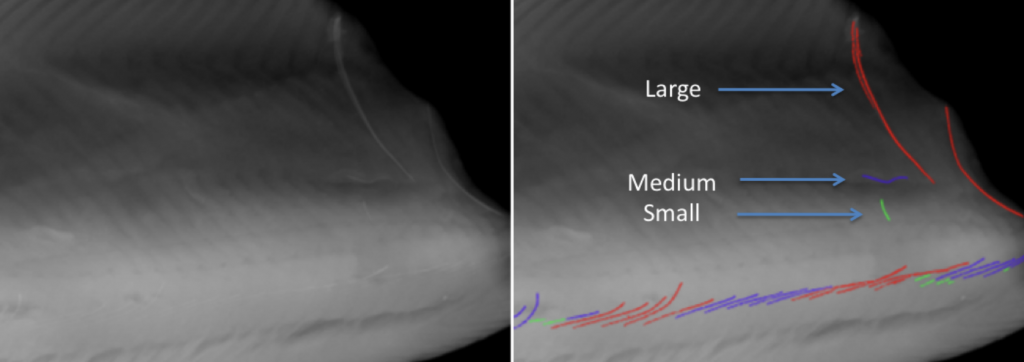

Detection of Fishbones with X-rays

In countries where fish is often consumed, fish bones are some of the most frequently ingested foreign bodies encountered in foods. In the production of fish fillets, fish bone detection is performed by human inspection using their sense of touch and vision which can lead to misclassification. Effective detection of fish bones in the quality control process would help avoid this problem. For this reason, an X-ray machine vision approach to automatically detect fish bones in fish fillets was developed. In our experiments, salmon X-ray images using 1010 pixels detection windows and 24 intensity features (selected from 279 features) were analyzed. The methodology was validated using representative fish bones and trouts provided by a salmon industry and yielded a detection performance of 99%. We believe that the proposed approach opens new possibilities in the field of automated visual inspection of salmon, trout and other similar fish.

Automated Fish Bone Detection using X-ray Testing. Mery, D.; Lillo, I.; Loebel, H.; Riffo, V.; Soto, A.; Cipriano, A.; Aguilera, J.M. Journal of Food Engineering (2011).

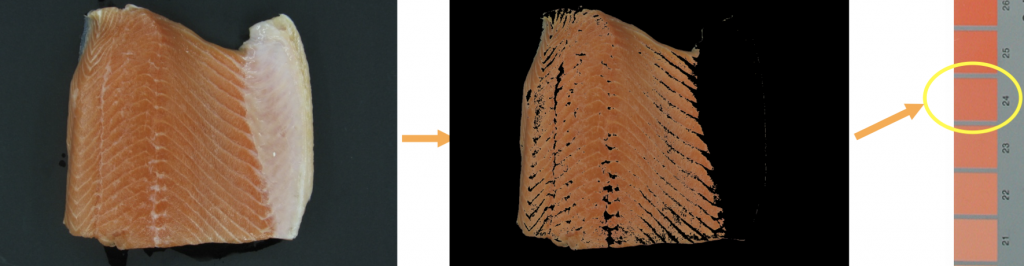

Color Analysis of Salmons

We developed a method and system for real-time automatic analysis of the quality of samples of processed fish meat based on the external appearance thereof, sail samples traveling on a conveyer belt such that surface defects can be detected and the fish meat can be sorted according to quality standards.

Method and system for real-time automatic analysis of the quality of samples of processed fish meat. Aguilera, J:M.; Cipriano, A.; Mery, D.; Soto, A. EP Patent 2,503,331 WO Patent WO/2011/058,529

Nutrition Analysis using Food Image Recognition

We developed a system and method for determining a nutritional value of a food item. The system and method utilizes a food container as a model to adjust various types of distortions that exists in an instant image of the food container that retains the food item. The instant image may be compared to the model image of the food container to correct any distortions. The food container includes a boundary which has a predetermined color. The predetermined color of the boundary can be used to adjust the color configuration of the instant image, thereby increasing the accuracy of the food identification. See SmartPlate.

System and method for nutrition analysis using food image recognition. Ortiz, A.; Mery. D. Patent Number: 9349297, 2016.